Optimizing Mixing Efficiency: The Role of Computational Fluid Dynamics (CFD) analysis in Agitation Processes

Computational Fluid Dynamics (CFD) analysis plays a crucial role in the pharmaceutical and chemical process industries, offering a powerful tool for optimizing and troubleshooting various processes. By simulating fluid flow, heat transfer, and mass transfer, CFD allows for virtual experiments and insights into process behavior, leading to reduced costs, improved efficiency, and faster development cycles.

Computational Fluid Dynamics (CFD) analysis in the Pharmaceutical Industry

Computational Fluid Dynamics (CFD) analysis serves as an essential resource in the pharmaceutical sector, facilitating process optimization, enhancing product quality, and streamlining manufacturing operations. It allows for virtual simulations of fluid dynamics and heat transfer, which assist in equipment design, process validation, and problem solving.

Applications of CFD in the Pharmaceutical Industry

1. Process Optimization : CFD helps optimize various unit operations like mixing, blending, and coating by visualizing flow patterns, identifying dead zones, and optimizing equipment parameters.

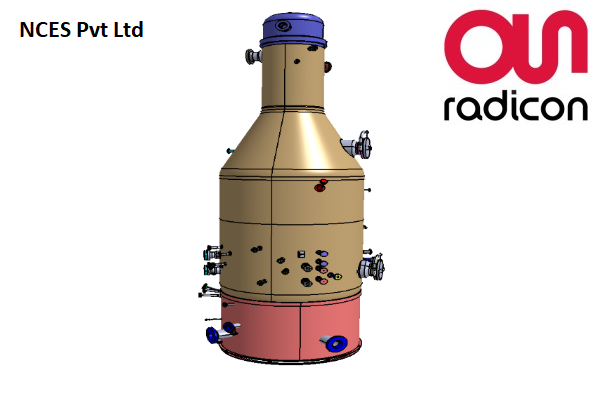

2. Equipment Design : CFD simulations allow for virtual design of equipment like tanks, bioreactors, and pipelines, ensuring optimal performance and minimizing potential issues.

3. Validation of Pharmaceutical Processes :CFD can predict fluid behavior under various conditions, validating processes and ensuring compliance with regulatory standards.

4. Troubleshooting :CFD can identify the root cause of issues like non-uniform mixing, product damage, or equipment malfunctions.

5. Scale-up and Scale-down : CFD simulations can help predict how a process will behave at different scales, aiding in the transition from small-scale research to large-scale manufacturing.

CFD analysis

Multi phase flows

Chemically reactive flows

Conduction, convection and radiation heat transfer

combustion

Agitators mixing analysis

Conjugate heat transfer analysis

HVAC CFD analysis

Clean room CFD analysis

Finite Element Analysis

Static, Dynamic analysis

Linear, non linear analysis

Structural design optimization